Hydraulic systems play a crucial role in various industries, from manufacturing and construction to automotive and aerospace. These systems use fluid power to perform tasks efficiently and precisely, making them an indispensable part of modern industrial operations. To better understand the importance of hydraulic systems https://hydro-funk.com/, it’s essential to explore the components, their suppliers, and the role they play in maintaining industrial efficiency.

What Are Hydraulic Components?

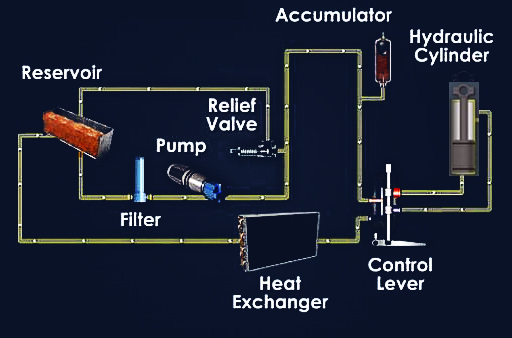

Hydraulic components are the building blocks of hydraulic systems. These parts work together to transmit power using pressurized fluid, usually oil or water-based solutions. By converting mechanical energy into hydraulic energy, these systems perform complex tasks like lifting, pressing, or moving heavy objects with minimal effort.

Key components of a hydraulic system include:

- Hydraulic Pumps: Responsible for converting mechanical energy into hydraulic energy, these pumps create the pressure necessary to move fluid.

- Valves: Control the direction, flow rate, and pressure of the hydraulic fluid.

- Cylinders: Convert hydraulic energy back into mechanical energy, performing tasks like lifting or pressing.

- Hoses and Tubes: Serve as conduits for the hydraulic fluid.

- Reservoirs: Store hydraulic fluid and ensure the system operates smoothly.

- Filters: Remove contaminants from the fluid, ensuring optimal performance and longevity of the system.

The Role of Hydraulic Component Suppliers

Finding a reliable supplier of hydraulic components is critical for businesses relying on hydraulic systems. Suppliers provide high-quality parts, ensuring durability, precision, and compatibility with industrial equipment.

A trusted hydraulic components manufacturer delivers:

- Customization: Tailored components to meet specific industrial needs.

- Quality Assurance: Adherence to industry standards and rigorous testing for durability.

- Comprehensive Solutions: From hydraulic pumps to filters, a one-stop-shop for all hydraulic needs.

- After-Sales Support: Maintenance, repairs, and replacements to ensure continuous operation.

Applications of Hydraulic Systems

Hydraulic systems are versatile and can be found in a wide range of industries. Here are some key applications:

- Construction Equipment: Excavators, bulldozers, and cranes rely heavily on hydraulic systems for movement and control.

- Manufacturing: Hydraulic presses and machines streamline processes like molding, stamping, and assembly.

- Automotive: From brakes to lifts, hydraulic systems enhance vehicle safety and functionality.

- Aerospace: Critical for landing gear, steering, and other high-precision operations.

Hydraulic Equipment and Industrial Suppliers

Industrial hydraulic suppliers play a pivotal role in ensuring the smooth operation of hydraulic systems. They provide components such as pumps, valves, and filters while offering technical support to maximize efficiency. Many suppliers specialize in hydraulic equipment tailored to specific industries, enabling businesses to source everything from individual components to fully integrated systems.

When choosing a hydraulic equipment supplier, consider:

- Reputation: Look for suppliers known for quality and reliability.

- Inventory: A diverse range of components ensures compatibility with various systems.

- Expertise: Suppliers with industry knowledge can offer valuable advice and solutions.

- Support Services: Maintenance, repairs, and technical assistance are critical for uninterrupted operations.

Components of a Hydraulic System in Detail

Each component of a hydraulic system serves a specific function:

- Hydraulic Pumps: Generate the pressure needed to move fluid through the system.

- Cylinders and Motors: Perform mechanical work like lifting or rotating objects.

- Control Valves: Manage the flow and direction of fluid for precise operations.

- Filters and Reservoirs: Maintain fluid cleanliness and storage.

Proper maintenance of these components is essential to avoid downtime and ensure peak performance.

Benefits of Hydraulic Systems

Hydraulic systems offer several advantages over mechanical or electrical systems:

- High Efficiency: Capable of transmitting large amounts of power with minimal energy loss.

- Compact Design: Smaller components make these systems ideal for space-constrained applications.

- Precision Control: Valves and sensors provide accurate adjustments for delicate tasks.

- Durability: Robust components withstand high-pressure environments and harsh conditions.

Future of Hydraulic Components

As industries embrace automation and sustainability, hydraulic components are evolving. Manufacturers are focusing on energy-efficient designs, eco-friendly fluids, and smarter systems with integrated sensors for real-time monitoring. These innovations ensure hydraulic systems remain relevant and reliable in the face of changing industrial demands.

Conclusion

Hydraulic components are the backbone of countless industrial systems, enabling smooth, efficient, and precise operations. Whether you need hydraulic pumps, valves, or entire systems, choosing the right supplier is essential to ensure quality and reliability. With the right components and maintenance, hydraulic systems can continue to drive industrial innovation and productivity for years to come.

Read more: Lucía Méndez Joven: The Early Years of a Timeless Icon of Mexican Entertainment